19 Aug 2021• Knowledge

Invest in safety that meets the requirements

Elimination of hazards in a work environment is hard work, and it may be difficult due to human error and technical failures. Nonetheless, as a business leader you always have a responsibility for your employees' safety. One major factor in reducing personal injuries in workplaces is to actively ensure that work equipment meets the current machinery directive.

Stay informed of the directives

The Machinery Directive 2006/42/EC concerns all new products on the EU market. The directive includes legal requirements to ensure safety, which means that machines and equipment must meet the essential requirements outlined in the directive to be placed on the market.

If machinery which does not meet the safety requirements is placed on the EU market it can:

- be withdrawn

- be prohibited on the market

- the authorities may restrict the free circulation of that type of equipment in the market

Therefore, manufacturers must ensure that products meet the safety and health requirements of the directive, which can be done by applying European harmonized standards. These standards are tools which help to comply with the law when elaborating new products. Harmonized standards listed in the EU's Official Journal are consistent with the directives. This simply implies that if you follow the applicable standards, you have correctly applied the directive's respective requirements. Thus, you may safely CE mark the product.

For business leaders it is crucial to always be aware of the safety of their employees and equipment. It is essential to maintain a safe work environment, stay informed and updated on current legislation, EU directives, certifications, rules and requirements. An important information source is the official website of the EU. Axelent's Safety Hub will now help you to stay well updated and explains many complex concepts in a down-to-earth approach.

What is the purpose of the Machinery Directive 2006/42/EC?

- To improve safety around machines with moving parts. The directive covers requirements for preventing accidents in industrial machinery.

- It intends to harmonize the previously divergent requirements for achieving health and safety in the EU.

- It intends to ensure the free circulation of machinery on the EU-market.

Who is affected by the directive?

- Regulations and requirements of the directive apply to manufacturers of machine and safety systems, machine distributors, importers, and users. It is applicable in the EU, the countries of the EEA and Turkey.

- The machinery directive only applies to new products on the EU market and products that have been so substantially modified that they come under the requirements.

What is significant to be aware of regarding the directive?

- Due to an ongoing revision process of the directive, it is crucial to constantly be updated. Particularly, the numerous standards used to detail the requirements of the directive are updated frequently.

- Since 2009 the former directive 98/37/EC has been replaced by the current Machinery directive 2006/42/EC. Although the directive does not contain radical changes, it has refined some concepts and added more stringent requirements for instance concerning reliability of control systems.

- In March 2021 the EU Commission published a proposal for a complete revision of the Machinery Directive, which will probably be turned into the new Machinery Regulation by 2023/2024.

All businesses have the responsibility of creating a safe working environment for their employees, and the matter of safety should always permeate every company. Using safe machines results in a safe environment and reduces the social cost of injuries and accidents.

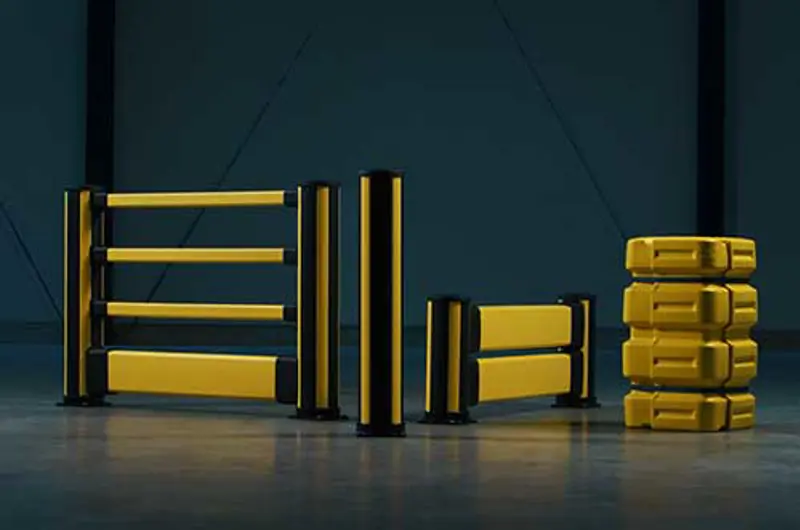

To us, as a manufacturer of machine protection systems, it is important to be able to offer products that meet the standards and requirements, while at the same time contributing to the growth of safety awareness and knowledge in the market. Active involvement in the development of directives and standards enable this.

Working with the Swedish Institute of Standards (SIS)

SIS is part of a network that develops international standards. Here, stakeholders can take initiative in developing standardization. This increases knowledge, promotes competitiveness on the market and contributes to sustainable development of society.

Sven Toftgård, responsible for the machine safety products at Axelent, is involved in Axelent's work with SIS.

- Being a representative, you are given the opportunity to consistently take part in the development of machine safety and influence the contents of standards.

Sven informs that the process of revision of the machinery directive is ongoing, which is mostly due to the rapid digital development and the challenges it raises.

- "As a manufacturer of machinery and safety products, working with SIS gives us the possibility to constantly be one step ahead and receive information regarding new standards and possible changes at an early stage", Sven says.

A glimpse of the international market

What does it look like in the rest of Europe then? Julien Colson, working in Axelent's technical department for the French market says:

- "Most of the French companies I work with follow the laws and guidelines existing. European standards have many similarities with standards that apply in the rest of the world. "

The awareness concerning the need to work actively toward safety work is growing. To improve safety in workplaces, Julien suggests Axelent's Safety Book to be a rich source of information and advises companies on how to think concerning improving the safety of their employees:

- “To be an entrepreneur today, it’s key to stay up to date with the latest standards and directives in order to succeed on the market”.

By investing in machine protection that meets the directives you:

- protect your employees

- save money on injuries that can be prevented

- offer your employees a safe working environment

- optimize profitability of your company

- avoid unnecessary downtime in production, which can have devastating financial consequences.