Chapter 3.3

Protective bonding of guard fencing

Electrical risks posed by guards need to be understood and considered. Usually, guard fencing and railing is made of electrically conductive materials, steel or aluminum. Therefore, guards and railing may become live, posing the risk of people being exposed to electric shock when touching them. In a worst-case scenario serious injury or death could result.

How could a guard fence become live?

While there are several possible reasons, these three critical factors must be considered during any risk assessment to ensure safety:

- Live machine parts

The machinery surrounded by a guard fence may be charged electrically differently from the fence itself. If someone touched both a charged machine surface and the fence, then they would suffer an electric shock. This is relevant if the distance between machine surfaces and the fence is less than 2500 mm (roughly the largest distance a person can span with outstretched arms). - Foreign voltage

A broken live wire (for instance, from an electric tool or lamp used during maintenance work) might touch a metallic fence part. The fence would then conduct a “foreign voltage”. - Currents induced in the fence

Strong electric fields near a fence might induce a current in the fence. This is not a frequent problem but may occur if very large electric motors (e. g., the motor of a rail vehicle) run near the fence. Large heaters (installed for instance in an industrial furnace) or lightning that hits the ground near the building may also generate strong fields that can induce a current in a metallic fence.

Why include fencing in the protective bonding circuit?

A voltage charge in a fence or a current induced in it will not always be hazardous. Much depends on the ground connections on site.

Some machine manufacturers and some operating companies will decide to include guard fencing in the protective (equipotential) bonding circuit of the machinery it surrounds. The safeguarding standard ISO 14120:2015 recommends considering whether guards are “extraneous conductive parts” of the machinery which must be connected to the protective earth conductor system of the machinery (see ISO 14120 clause 5.13 and IEC 60204-1:2018 clause 3.1.28). The decision should be made during risk assessment by a qualified electrical engineer or electrician who is aware of the conditions at the installation site.

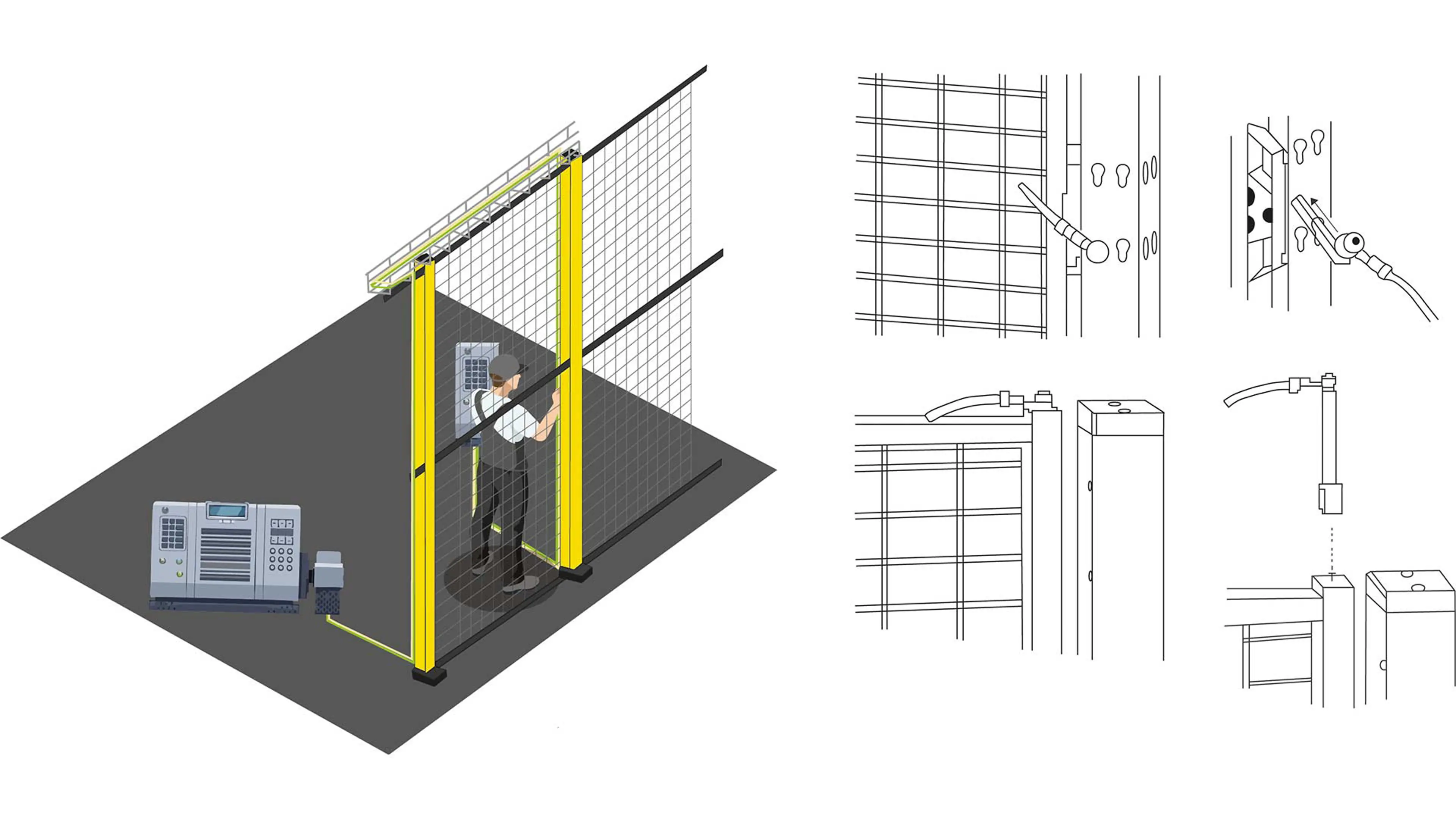

Technical illustration showing the protective bonding of guard fencing in an industrial setting. The diagram details grounding connections, cable attachments, and proper installation methods to mitigate electrical risks and enhance workplace safety.

Including guard fencing in the protective bonding circuit

Some simply interconnect the posts and panels and then connect one end (or both) to the protective bonding circuit of the machine. While this generally works, the electric safety standards say that one must not use the fence itself as the bonding conductor.

Why is it not sufficient to simply interconnect posts and panels?

If just one panel is removed from the fence or one connection fails, the bonding circuit is interrupted.

It is better to run a separate bonding conductor along the entire fence and to connect each post and panel to it. Then the entire system will continue to function even if individual panels are removed or disconnected. Axelent optionally supplies connectors for posts and panels that can be installed without having to drill any holes. The bonding conductor can be laid in an Axelent wire tray fastened to the fence.

For more information, please refer to EN (IEC) 60204-1:2018 section 8.1 and 8.2.